Circulation Pumps in Boiler Systems

Understanding Boiler Circulator Pumps

Circulation pumps, often called centrifugal pumps, are a critical component in hot water boiler systems. They move water from the heat source through piping to radiators or baseboards and back to the boiler. These pumps rely on centrifugal force to circulate water, with the impeller spinning to push water through the system. Unlike pressure pumps, circulators are designed primarily for flow and distribution rather than boosting pressure.

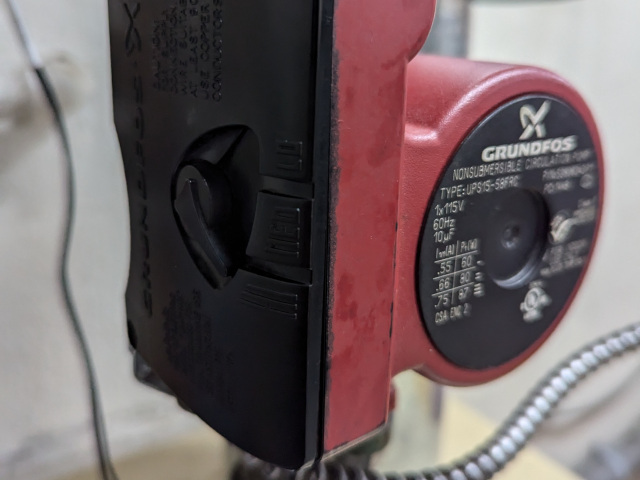

Popular circulation pump brands commonly encountered during boiler repairs include Bell & Gossett 100 Series, Taco 007, and Grundfos UPS26–99. These pumps are valued for reliability, simplicity, and long service life, which averages around 10–15 years depending on usage, water quality, and maintenance.

When planning installation or replacement, several key considerations help ensure optimal performance:

- Zoning: Multi-zone systems often require multiple circulators to independently control heating in different areas. Proper zoning ensures energy efficiency and consistent comfort.

- Installation Location: Pumps should be installed close to the boiler and downstream of the expansion tank to prevent air locking. Proper alignment and piping support reduce vibration and wear.

- System Flow Rate: Selecting the right pump size for your boiler system ensures adequate flow without excessive energy use or cavitation.

- Maintenance: Routine inspection for leaks, noise, and vibration prolongs pump life and helps avoid unexpected failures.

In this guide, we will explore common problems with circulation pumps, step-by-step troubleshooting, and when it’s appropriate for a homeowner to perform DIY checks versus calling a professional. For more advanced boiler repairs, see our boiler troubleshooting guide.

Many homes still use legacy pump models due to their simplicity and reliability. Modern circulator pumps offer advanced features such as electronically commutated motors (ECMs), digital displays, and variable flow capabilities, which can improve efficiency and comfort. These newer features will be explored in future articles.

Fun fact: In 2011, Xylem Inc. acquired Bell and Gossett, adding their products to a larger portfolio of hydronic system solutions.