This guide explains how relative humidity affects walk-in cooler and freezer performance, food quality, and long-term equipment reliability.

The Role of Relative Humidity in Food Preservation

Owners of cold storage rooms and HVAC professionals often prioritize maintaining the target temperature of the system while overlooking relative humidity (RH). However, a well-designed medium-temperature refrigeration system must regulate both temperature and RH to ensure optimal food preservation. In this guide, we’ll explore how refrigeration systems control RH and how temperature fluctuations affect the ability to maintain the ideal conditions for different types of food.

When it comes to preserving food, both temperature and relative humidity (RH) within a refrigerated case are critical. When considering a walk in cooler repair or maintenance. Let’s look at what happens when RH is too high or too low:

- High RH (above 95%): This can lead to the growth of mold and slime, especially on stored meats.

- Low RH: Can cause excessive dehydration, which negatively impacts food quality.

How Evaporator Temperature Difference Affects RH

One key factor affecting relative humidity (RH) is the evaporator temperature difference (TD). This refers to the difference between the refrigerant’s saturation temperature inside the evaporator coil and the temperature of the air entering the coil, also known as the return air temperature. In this context, TD is distinct from Delta-T and Superheat—common concepts in air conditioning refrigeration systems—making it important for HVAC technicians to understand its specific role.

The Role of Evaporator Temperature Difference (TD)

The TD directly influences how much moisture is removed from the air inside the refrigerated case:

- Greater TD: More moisture is removed, resulting in a lower RH inside the case.

- Lesser TD: Less moisture is removed, leading to a higher RH in the case.

For example, a typical walk-in cooler is designed with an evaporator TD of around 10˚F (with entering air at 35˚F and a coil temperature of 25˚F). This results in an RH of approximately 85%, which is ideal for long-term food storage.

Why Maintaining Proper RH Is Important for Business

Food products, particularly meats, have a high water content, making it essential to maintain the appropriate relative humidity (RH) in refrigerated cases. The correct RH helps preserve the product’s weight and shelf life, which can significantly affect profitability. In fact, maintaining proper RH directly impacts profitability. During a walkin cooler install, maintenance or a walk in freezer repair If the RH is too low:

- Food products may dry out, leading to reduced weight.

- Product shelf life may decrease, ultimately affecting sales and profits.

This article focuses on relative humidity and evaporator design, but RH is only one part of overall system performance. For a broader discussion on lifecycle decisions, including when ongoing adjustments are no longer effective, see this walk-in cooler repair vs replacement resource.

Common RH for Reach-In vs Walk-In Coolers

While cold storage rooms are designed to cool and preserve food, it’s important to distinguish between walk-in coolers and smaller refrigeration units such as display cases, merchandisers, beverage coolers, and reach-in coolers. A 10˚F evaporator temperature difference (TD) is effective for walk-in coolers, but not all refrigeration systems follow this design. Smaller units, like reach-in coolers, often have more compact evaporators, leading to a higher TD—typically around 20˚F.

Reach-in Coolers vs. Walk-in Coolers

Reach-in coolers may use an evaporator designed with a 20˚F TD such as the case for Beverage Cases or Delfield Prep Tables among others, which leads to a lower RH of about 65%. To prevent dehydration, food in these cases is either wrapped or stored for short periods—typically less than 24 hours.

These differences in TD also explain why suction pressures may vary between similar refrigeration systems. Lets make the assumption that the target box temperature is 35F and thus the return temperature is 35F. For example:

| Type | Target TD | Coil Temp | PSIG R134A | PSIG R404A | PSIG R22 |

|---|---|---|---|---|---|

| Walk-in Cooler | 10 | 25 | 22 | 62 | 63 |

| Reach-in Cooler | 20 | 15 | 15 | 49 | 50 |

- Walk-in Cooler: If both a walk-in cooler and a reach-in cooler have the same entering air temperature (35˚F) and use the same refrigerant (R404A), the walk-in cooler's evaporator coil temperature would be 25˚F. The suction pressure would be approximately 62.7 psig with a TD of 10˚F.

- Reach-in Cooler: A reach-in cooler, with a coil temperature of 15˚F and a 20˚F TD, would have a suction pressure of approximately 49 psig.

Although both coolers maintain the same case temperature, they operate with different RH levels and slightly different suction pressures due to varying TD values.

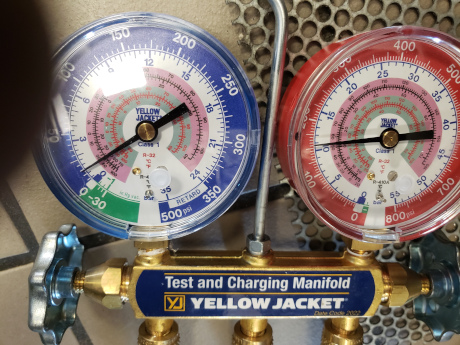

Many DIYers and HVAC technicians rely solely on refrigerant pressure to charge a system, which may achieve the desired box temperature but fails to consider proper system operation, product longevity, and profitability—knowledge that sets average HVAC technicians from true HVAC Experts apart.

Ideal RH for Walk-in Boxes

The following table summarizes the recommended Relative Humidity (RH) for various types of walk-in coolers and freezers. These values are widely agreed upon by reputable manufacturers and the scientific community to ensure proper storage conditions.

| Section | Box Temp (°C) | Box RH (%) |

|---|---|---|

| General Cooler | 35 | 84 |

| Convenience Store | 38 | 78 |

| Produce | 40 | 87 |

| Beer | 38 | 75 |

| Flower | 38 | 87 |

| General Freezer | -10 | 95 |

| Ice Cream | -15 | 95 |

| Wine | 55 | 65 |