Boiler Air Removal Overview

Air trapped in hydronic hot water boiler systems can quietly reduce comfort, increase energy use, and strain critical components. Homeowners often notice the problem through unusual noises, cold radiators, or uneven heating, but the underlying causes are not always obvious. Left unaddressed, trapped air can interfere with circulation and lead to long-term performance issues.

In this guide, we explain how air enters a boiler system, the real impact on efficiency and reliability, the devices designed to remove air automatically, and practical troubleshooting steps you can take when problems appear.

Why Air in a Boiler Causes Heating Failures and No Heat

Hot water boiler systems rely on continuous water circulation to move heat from the boiler to radiators or baseboards. When air becomes trapped inside the system, circulation is disrupted because air compresses while water does not. Even small air pockets can block flow, reduce heat transfer, and prevent zones from heating properly.

In practical terms, air in a boiler system often behaves like a circulation failure. Reduced circulation leads to cold radiators, uneven heating, rising pressure, and noisy pipes. As these symptoms worsen, the boiler may short cycle, lock out for safety, or fail to deliver heat at all.

This is why persistent air problems frequently escalate into a no-heat condition that requires professional boiler service. Understanding how air affects circulation helps homeowners decide when simple bleeding is enough — and when deeper system diagnostics are necessary.

Looking for a specific solution? Jump directly to symptoms, venting devices, troubleshooting steps, or preventative tips below.

Symptoms of Air in Boiler Systems

Air trapped in a hot water boiler or hydronic heating system often produces noticeable symptoms. Homeowners commonly experience one or more of the following warning signs when air builds up in the system:

- Gurgling or hissing noises from baseboards or pipes: As hot water moves past trapped air pockets, it creates bubbling or rushing sounds.

- Cold spots in radiators: Air prevents hot water from reaching the upper sections of the radiator, leaving the top cold while the bottom remains warm.

- Erratic boiler pressure readings: Fluctuating pressure on the gauge may indicate air trapped inside the system.

- Reduced heating efficiency: Air acts as an insulator, limiting heat transfer and increasing energy consumption.

- Circulator pump noise or premature failure: Pumps struggle to move water efficiently when air is present, increasing wear and the risk of cavitation.

- System lockout or safety shutdown: Modern heating systems may shut down automatically when trapped air disrupts normal operation.

When air-related symptoms return repeatedly, the underlying issue is often a failing pressure-reducing valve, undersized or waterlogged expansion tank, or a circulator that can no longer maintain proper flow — conditions that bleeding alone cannot correct.

If you recognize these symptoms, the sections below explain how to identify the cause and remove air safely. In many cases, however, contacting a licensed professional for home boiler repair ensures proper diagnosis and long-term reliability.

Impact of Trapped Air on Boiler Performance

Trapped air inside a hot water boiler system affects more than comfort. Because air compresses while water does not, even small pockets can disrupt flow, pressure balance, and heat transfer throughout the system. Air can also cause mechanical issues, potentially jamming circulator pumps or triggering safety devices like the low water cutoff.

- Corrosion Risks: Oxygen in the system accelerates internal corrosion of steel and cast-iron components, shortening boiler life.

- Decreased Efficiency: Air is an insulator it reduces heat transfer and forces the boiler to run longer to meet demand.

- Component Stress: Circulator pumps and valves work against air pockets, increasing wear, noise, and the risk of premature failure.

- Imbalanced Heat Distribution: Zones or radiators may receive uneven flow, resulting in cold rooms and inconsistent temperatures.

Over time, these conditions can compound, turning a minor air issue into recurring lockouts, pump damage, or costly system repairs if not corrected.

Whole-System Air Removal Devices

Proper air removal is critical for efficient and reliable hot water boiler operation. Whole-system air removal devices are installed near the boiler, usually right after the pressure reducer, in a location where recirculated water flows. These devices help eliminate trapped air before it reaches radiators or baseboards, preventing uneven heating, gurgling noises, and premature wear on pumps and valves. For a detailed guide on troubleshooting and repairing hydronic boilers, see our boiler troubleshooting guide.

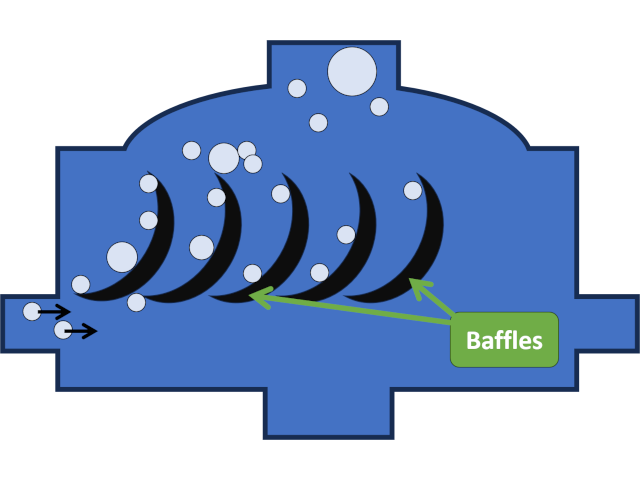

Boiler Air Separator / Purger (Scoop)

The scoop, or purger, separates air from circulating water by diverting flow over internal baffles, allowing air bubbles to rise to the top. It’s important to note that the separator itself does not remove air; it channels bubbles toward an automatic vent, which performs the actual evacuation.

Popular manufacturers include Watts, Amtrol, Bell and Gossett, TACO, and Honeywell.

Automatic Air Vents

Automatic air vents evacuate air from a hot water boiler system without manual intervention. A float mechanism opens when excess air is present, releasing it safely. Installing these vents at the highest points in the system ensures maximum efficiency and prevents trapped air from causing uneven heating or noisy pipes.

Available options include one-time-use models (77, 78, 79) that require replacement if clogged, and serviceable models like the Model 97 from Bell and Gossett or Caleffi, which can be opened and maintained in case of malfunction.

One-Time Use Vent

Repairable Vent

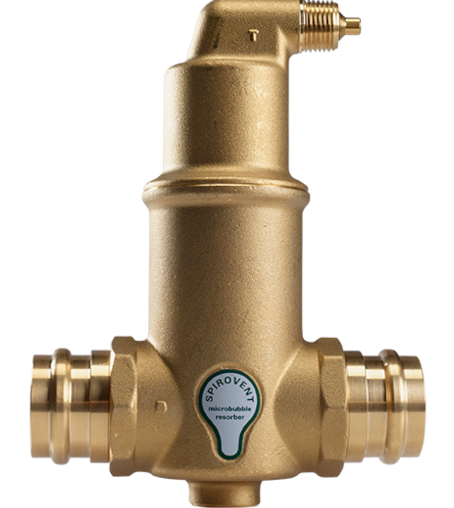

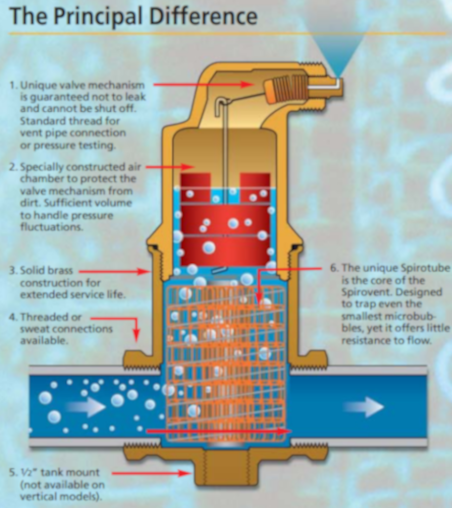

Microbubble Air Eliminators – SpiroVent

Microbubble air eliminators, like SpiroVent, efficiently remove free, entrained, and dissolved air from hydronic systems. They use woven copper wire soldered to a tube to create low-velocity zones, allowing bubbles to rise to an integral float valve for automatic evacuation.

Note: According to SpiroVent, it eliminates 100% of free air, 100% of entrained air, and up to 99.6% of dissolved air. Brass construction improves durability compared to heavier models.

Engineering Insight: Controlling fluid velocity is key — slower flow through these devices ensures maximum air removal. HVAC pros leverage velocity control for system performance, similar to airflow optimization in filters.

Terminal-Wise Air Removal: Baseboards and Radiators

Even with properly installed whole-system air removal devices, air can still accumulate in terminal units such as baseboards and radiators. Removing air at the terminal level ensures consistent heat distribution and prevents cold spots or gurgling noises. Always turn off the boiler and allow water to cool before starting.

Air Removal from Baseboards

Baseboards typically have a vent valve, also known as a bleeder tee. To remove trapped air:

- Place a cloth or towel under the valve to catch any water.

- Slowly open the bleeder valve using the correct key.

- Allow air to escape until water flows steadily.

- Close the valve and check the system pressure at the boiler.

Tip: Using an improvised tool (like a screwdriver) can damage the valve. Always use the proper key to avoid leaks or repairs.

Air Removal from Radiators

Radiators are vented in much the same way as baseboards:

- Locate the bleeder valve at the top of the radiator.

- Place a cloth and cup under the valve to collect water.

- Open the valve slowly to release trapped air until a steady stream of water appears.

- Close the valve and verify boiler pressure is within recommended range.

This process may need to be repeated periodically, especially after adding water to the system or after servicing.

Additional Notes for Terminal Air Removal

- Bleeding baseboards and radiators is a simple DIY task but must be done correctly to avoid damage or leaks.

- Checking system pressure after bleeding is crucial — low pressure can trigger pump strain or boiler lockouts.

- Regularly venting terminals complements whole-system air removal devices, ensuring consistent heat and longer equipment life.

Troubleshooting Air-Related Boiler Issues

Before troubleshooting a hot water boiler system, it’s strongly recommended that you understand the key components discussed earlier in this guide. Even with properly installed air-removal devices — and even after performing basic DIY maintenance — air can still develop inside a hydronic system. Much like a carbonated beverage, dissolved air can come out of solution under the right conditions and create new air pockets.

Some steps below may overlap with the tune-up and preventative maintenance sections. This is intentional. Repetition ensures accurate diagnosis, system safety, and consistent heat throughout your home.

Step 1: Identify Signs of Air in the System

- Listen for unusual noises: Hydronic heating systems are designed to operate quietly. Gurgling, hissing, or rushing sounds from baseboards, radiators, or piping indicate trapped air and require attention.

- Inspect radiators and baseboards: Cold spots at the top of radiators or noticeably uneven heat along baseboards are classic signs of air pockets.

- Monitor boiler pressure: Erratic or fluctuating gauge readings can signal air in the system. When the boiler is operating at approximately 180°F, system pressure should typically be around 22 PSI.

Step 2: Bleed the System

- Turn off the boiler: Always allow the system to cool before bleeding air from any components.

- Locate bleed valves: Identify manual vents on radiators, baseboards, or high points in the piping (see Baseboard and Radiator Air Removal instructions).

- Release trapped air: Slowly open each valve until air escapes and a steady stream of water follows.

Step 3: Inspect Automatic Air Vents

- De-aerate the air vent: Carefully open the vent cap fully. Gently depress the internal stem (similar to a car tire valve) and allow air to escape until a small amount of water flows. Confirm the vent is unobstructed and that the internal float mechanism moves freely.

- Stuck or leaking vents: If the vent stem is seized, leaking continuously, or fails to release air, the automatic air vent should be replaced.

Step 4: Recheck Pressure and Temperature

- Cold system pressure: Slowly add water as needed to restore pressure to 12–14 PSI when the system is cold (approximately 70°F).

- Operating gauge values: Start the boiler and set the thermostat(s) to heating mode. For multi-zone systems, ensure all thermostats are calling for heat. Allow the boiler temperature to stabilize near 180°F, then confirm pressure is between 22–25 PSI.

- Critical safety warning: If pressure approaches 28 PSI, stop troubleshooting and contact a professional immediately. At 30 PSI, the pressure relief valve will open, potentially discharging hot water and flooding the area.

Step 5: Confirm Proper Circulation

- Circulator pump noise: The pump should run smoothly without gurgling, rattling, or cavitation sounds.

- Additional pump checks: The temperature of the pump inlet and outlet pipes should be nearly identical. A noticeable temperature difference suggests air pockets or restricted flow that may require whole-system bleeding. Under normal conditions, the pump should feel warm to the touch — not excessively hot.

If circulation noise or temperature imbalance remains after proper bleeding and pressure correction, the issue is usually hydraulic in nature — such as flow restriction, pump sizing mismatch, or air re-entering the system due to control or piping design — all of which require system-level diagnostics.

If air-related issues persist after completing these steps, or if pressure and temperature readings fall outside safe ranges, discontinue troubleshooting and contact a licensed HVAC professional. Proper diagnosis protects your boiler, your home, and your safety.

DIY Preventative Measures for Hot Water Boilers

Even with proper maintenance devices, trapped air can occasionally affect your boiler’s performance. Homeowners can perform a few simple preventive steps, but it’s important to know when to call a licensed HVAC professional. Annual professional maintenance is still highly recommended to ensure long-term reliability and efficiency.

Step 1: System Off and Cold – First Inspect for Water Leaks

Before starting any maintenance, turn off the boiler and allow the water to cool. Carefully inspect the boiler and surrounding piping for water leaks, rust, or corrosion.

Step 2: Bleed the Air Vent

Locate your boiler’s automatic air vent. Slightly open the cap to allow trapped air to escape — you should first see air, followed by a small amount of water. Replace the cap loosely so air can continue to vent as needed; avoid tightening it completely, which is a common DIY mistake. After bleeding, check the system pressure: it should read about 12–14 PSI when the system is cold (~70°F). Add water slowly to maintain this pressure.

Step 3: Power On and Heat the System

Turn on the boiler and set all thermostats to heating mode. For multi-zone systems, ensure every zone is calling for heat. When the boiler reaches ~180°F, the pressure should rise to 22–25 PSI. Monitoring both temperature and pressure is key for safe and efficient operation.

Step 4: Check Circulation and Terminal Units

- Ensure the circulator pump runs smoothly and quietly.

- Inspect radiators and baseboards: inlet pipes should be slightly hotter than outlet pipes, with no gurgling or hissing noises.

- Observe system cycling: ideally, it should run for longer periods (~1 hour) rather than short on/off cycles within 5 minutes, which can indicate air or pressure issues.

These DIY checks can be performed about once a month by someone familiar with boiler operation. However, if you notice persistent cold spots, unusual noises, fluctuating pressure, or short cycling that you cannot resolve, it’s important to stop and contact a licensed HVAC professional. Professionals can inspect air separators, automatic vents, and circulator pumps to ensure safe and efficient operation.

Pro Tip: Even with regular DIY maintenance, scheduling an annual professional service is highly recommended. This helps catch hidden issues early and keeps your boiler system reliable, efficient, and safe for years to come.